Product Description

CHINAMFG Is the China’s largest mining truck spare parts manufacturer.

With decades of years experiences in the fields of a sales for CHINAMFG /NHL truck parts a, we mainly carry the rigid truck

such as : TR100 parts ,TR70 parts, TR60 parts, TR50 parts ,TR45 parts, TR35 parts and

TA40 parts,TA30 parts,3307 parts,3305 parts,3304 parts,3303 parts.

electric drive such as MT4400 parts ,MT3700 parts ,NTE260 parts,NTE240 parts ,NTE200 parts.

| 9261065 | 15300946 | 9065718 | 274191 |

| 6525035 | 927 0571 | 15272571 | 15230178 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

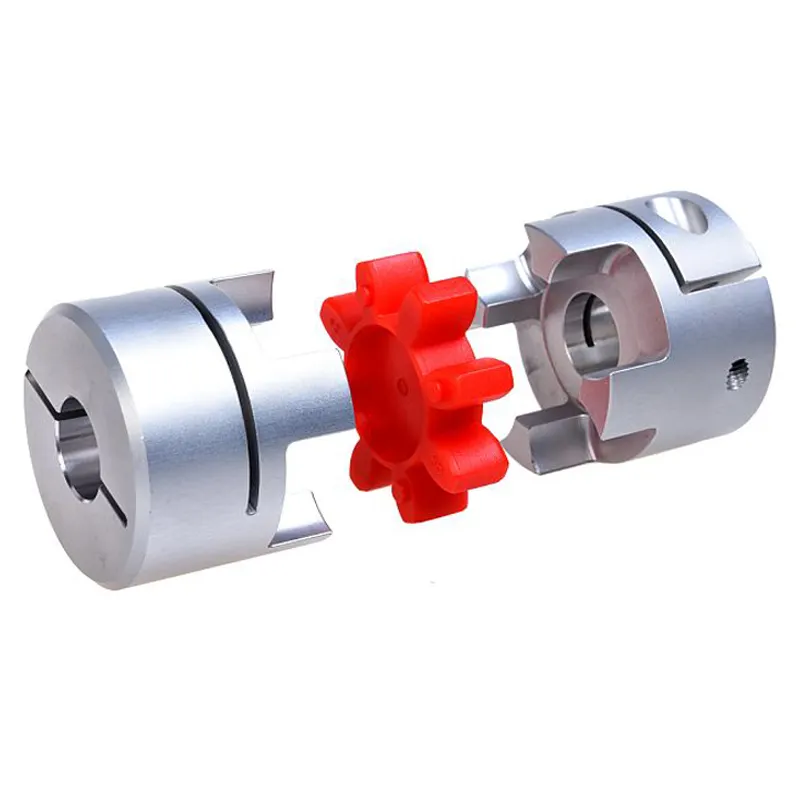

Usage of Jaw Couplings for Motor-to-Shaft and Shaft-to-Shaft Connections

Jaw couplings are versatile components that can be used for both motor-to-shaft and shaft-to-shaft connections in mechanical power transmission systems. Their design and features make them suitable for various applications:

- Motor-to-Shaft Connection: When connecting a motor to a driven shaft, jaw couplings are commonly used to transmit torque from the motor to the driven equipment. The motor’s shaft is inserted into one side of the jaw coupling, and the driven shaft is inserted into the other side. The elastomeric spider element in the coupling provides a flexible connection that accommodates misalignment and dampens vibrations, ensuring smooth power transmission from the motor to the driven shaft.

- Shaft-to-Shaft Connection: In cases where two shafts need to be connected directly, without a motor or other driving element, jaw couplings can be used for shaft-to-shaft connections. Both shafts are inserted into the respective sides of the jaw coupling, and the elastomeric spider element bridges the gap between them. This enables torque transfer between the two shafts while compensating for any misalignment that may exist.

Whether used for motor-to-shaft or shaft-to-shaft connections, jaw couplings offer the same advantages, including misalignment compensation, vibration dampening, and backlash-free operation (depending on the design). These features make them suitable for various applications across different industries, where reliable and efficient power transmission is essential.

Can jaw couplings be used in servo motor and stepper motor applications?

Yes, jaw couplings can be used in both servo motor and stepper motor applications, and they are commonly employed in such systems. The key factors that make jaw couplings suitable for these motor types are their ability to handle misalignment, their torsional flexibility, and their compact and lightweight design.

In servo motor applications, jaw couplings are chosen for their high precision and responsiveness. Servo motors require couplings that can transmit torque with minimal backlash and provide accurate motion control. Jaw couplings achieve this by maintaining a tight fit between the elastomer spider and the coupling hubs, minimizing backlash and ensuring precise torque transmission. The elastomer spider also dampens vibrations and shocks, contributing to smoother motor operation and increased system stability. Additionally, the compact size and low inertia of jaw couplings make them ideal for high-speed servo motor applications where quick acceleration and deceleration are crucial.

In stepper motor applications, jaw couplings are preferred for their ability to handle misalignment. Stepper motors often have shaft misalignment due to manufacturing tolerances or other factors, and jaw couplings can accommodate both angular and parallel misalignment without imposing significant additional loads on the motor bearings. This helps to reduce wear and extend the life of the motor and coupling components. Moreover, stepper motors are commonly used in open-loop systems, where precise positioning and motion control are essential. Jaw couplings’ low backlash characteristics aid in achieving accurate positioning and eliminating any motion inaccuracies that might arise due to backlash in the coupling.

Overall, jaw couplings are well-suited for servo motor and stepper motor applications due to their precision, ability to handle misalignment, torsional flexibility, and low inertia. When selecting a jaw coupling for a specific motor application, it is essential to consider factors such as torque requirements, operating conditions, and motor specifications to ensure optimal performance and reliability in the system.

Materials Used in Manufacturing Jaw Couplings

Jaw couplings are commonly made from various materials, each offering different properties and suitability for specific applications. Some of the commonly used materials include:

- Polyurethane (PU): PU jaw couplings are known for their flexibility, high elasticity, and resistance to abrasion. They are ideal for applications requiring vibration dampening and shock absorption.

- Aluminum: Aluminum jaw couplings are lightweight, corrosion-resistant, and have good thermal conductivity. They are commonly used in low-to-medium torque applications.

- Steel: Steel jaw couplings offer high strength and durability, making them suitable for heavy-duty applications with high torque requirements.

- Stainless Steel: Stainless steel jaw couplings are resistant to corrosion and are often used in applications where there is exposure to moisture, chemicals, or harsh environments.

- Bronze: Bronze jaw couplings are known for their excellent wear resistance and low coefficient of friction, making them suitable for applications with high-speed and low lubrication.

- Acetal: Acetal jaw couplings provide good chemical resistance and low moisture absorption, making them suitable for applications where chemical exposure is a concern.

- Nylon: Nylon jaw couplings offer good strength, flexibility, and resistance to wear and chemicals, making them suitable for various industrial applications.

The choice of material depends on factors such as torque requirements, environmental conditions, operating speeds, and budget considerations. Engineers and designers select the appropriate material to ensure that the jaw coupling can perform optimally and withstand the demands of the application.

editor by CX 2024-05-06

by

Leave a Reply